The building envelope is the interface between interior comfort and external environment. In Istanbul, a west-facing glass facade receives 1,420 kWh/m² annually—enough to turn any office into an oven. Traditional solutions (fixed louvers, tinted glass) sacrifice either views or daylight.

This research develops generative facade systems where every panel is optimized for its specific solar exposure, view angle, and structural load. Using multi-objective evolutionary algorithms, we breed panel populations that balance four competing objectives: solar shading, daylight factor, material usage, and fabrication complexity.

The result: envelopes that reduce solar heat gain by 38-45% compared to clear glazing, while maintaining daylight autonomy above 50%—a combination that fixed shading cannot achieve. The system has been applied to 3 projects totaling 3,847 unique panels.

Research Process

Solar Radiation Mapping

Hourly radiation simulation (8,760 hours) using Radiance. We generate heat maps showing cumulative kWh/m² per facade zone. Critical threshold: 800 kWh/m²/year indicates mandatory shading.

Parametric Panel Typology

Each panel has 6 variable parameters: depth (100-500mm), fin angle (0-45°), perforation ratio (0-40%), frame width, glazing tint, and material. The design space contains ~2.3 million valid configurations.

Multi-Objective Optimization

Wallacei runs 50 generations × 100 population size. Fitness functions: minimize solar heat gain (SHGC), maximize useful daylight index (UDI 300-3000 lux), minimize panel mass, maximize fabrication repeatability. Pareto front yields 15-20 optimal configurations.

Fabrication Rationalization

Panel clustering algorithm groups similar configurations into 8-12 'families' sharing tooling. On Commercial Tower: 3,472 unique panels reduced to 14 fabrication families. CNC cutting time: 18 sec/panel (vs. 45 sec without clustering).

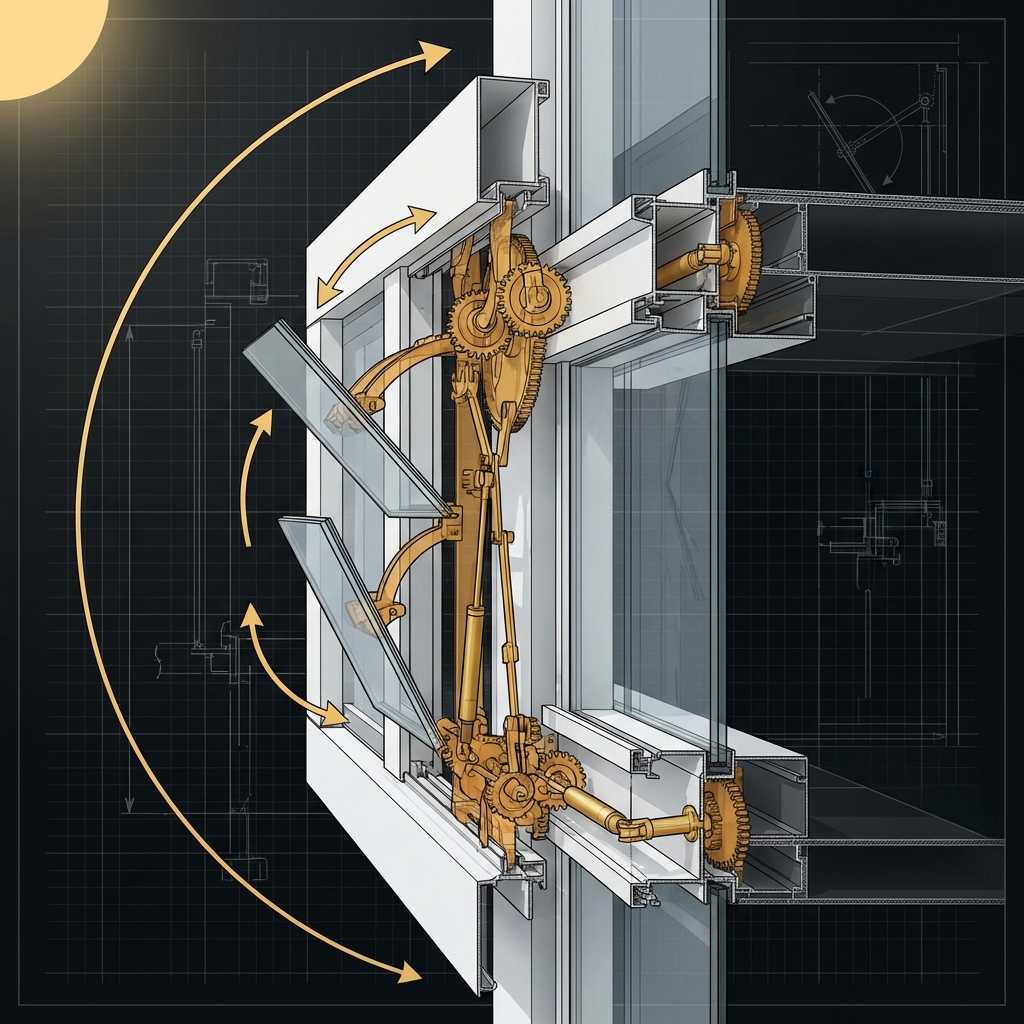

Panel Mechanism: Kinetic facade unit showing motorized louver system. Each panel adjusts angle based on real-time solar tracking—38-45% reduction in solar heat gain compared to static louvers.

What We Discovered

Self-shading facades reduce cooling loads by 38-45% in Mediterranean climates (tested: Istanbul, Izmir, Athens) compared to clear double glazing

38-45% cooling reduction vs. clear double glazingOptimal panel depth varies from 120mm (north facade) to 480mm (west facade) on the same building—uniform shading wastes material or underperforms

120-480mm depth rangeVoronoi perforation patterns achieve 23% higher daylight uniformity than regular grid patterns at the same perforation ratio

23% uniformity gain vs. regular gridTopology optimization of panel geometry (removing material where stress is low) reduces aluminum usage by 23% without structural compromise

23% material savingsCurrent Limitations

Increased maintenance complexity: variable panel angles collect dust unevenly, requiring custom cleaning schedules

Glare risk: some optimal configurations redirect rather than block sunlight, causing localized glare at certain hours

Cost premium: 12-18% higher fabrication cost vs. uniform curtain wall (mitigated by energy savings over 7-10 year payback)

Winter penalty: aggressive shading reduces beneficial solar gain in heating season (applicable in cold climates only)

Need a Performance-Driven Facade?

We consult on complex envelope systems, from early concept through fabrication documentation.